Stainless Steel 440C Balls are martensitic and hardened in nature, the hardness achieved is excellent and also is good wear resistant. The highest surface finishing and tight dimensional tolerances can be manufactured with this material.

Applications :

- High Precision bearings

- Aerospace

- Knotting devices

- Oil and Gas Industry

- Quick Release Couplings

- Automotive Industry

- Pharma Industry

Steel balls have good corrosion resistance and can withstand oil, petrol, steam and alcohol.

Chemical composition

|

%C

|

%Si

|

%Mn

|

%P

|

%S

|

%Cr

|

%Mo

|

| 0.95-1.20 |

1.00 max |

1.00 max |

0.040 max |

0.030 max |

16.00-18.00 |

0.75 max |

International Standards and material codes

|

USA

|

GER

|

FRA

|

RUS

|

CHN

|

JAP

|

| 440C |

1.4125 |

Z100CD17 |

95X18 |

9Cr18Mo |

SUS440C |

Technical Properties

|

Property

|

Type

|

U.o.M.

|

Values

|

U.o.M.

|

Values

|

| Hardness |

Mechanical |

[HRC] |

57 - 64 |

- |

- |

| Ultimate tensile strength |

Mechanical |

[MPa] |

1900 - 2000 |

[psix10^3] |

275 - 290 |

Size Range/ Grade selection

| Product |

Size Range |

U.o.M. |

Grade Capabilities |

| Balls |

3.00 mm to 76.20 mm |

[mm] |

GR.10 to GR.2000 as per any international standard. |

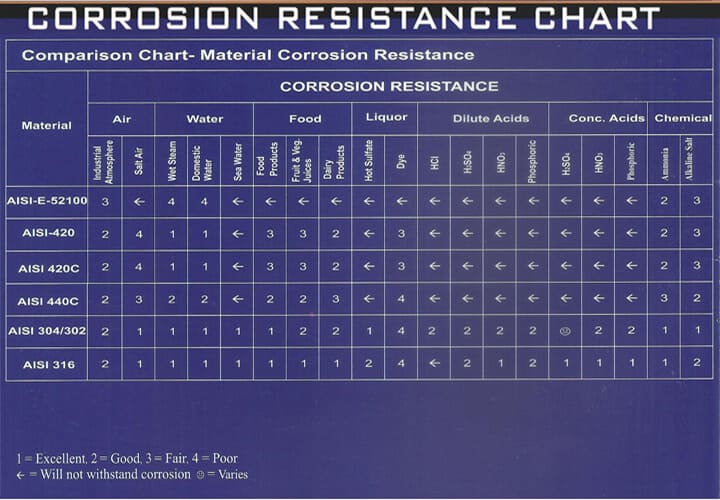

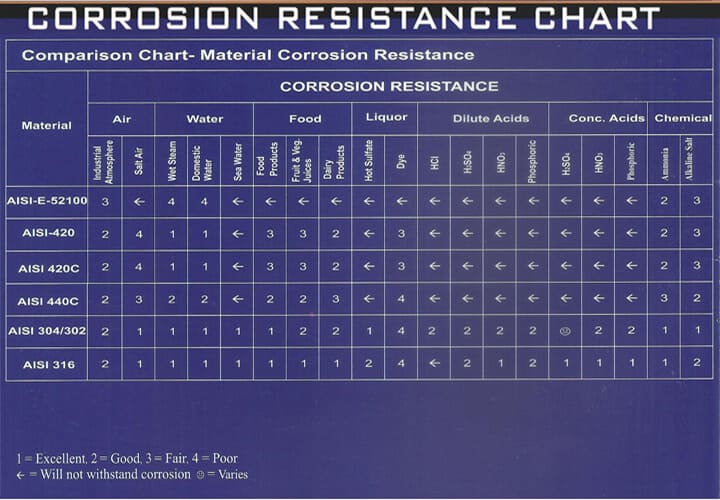

| Comparison Chart- Material Corrosion Resistance |

Material

|

CORROSION RESISTANCE |

| Air |

Water |

Food |

Liquor |

Dilute Acid |

Conc. Acid |

Chemical |

| Industrial Atmosphere |

Salt Air |

Wet Steam |

Domestic Water |

Sea Water |

Food Product |

Fruit & Veg. Juice |

Dairy Product |

Hot Sulfate |

Dye |

HCL |

H2SO4 |

HNO3 |

Phosphoric |

H2SO4 |

HNO3 |

Phosphoric |

Ammonia |

Alkaline Salt |

| AISI-E-52100 |

3 |

← |

4 |

4 |

← |

← |

← |

← |

← |

← |

← |

← |

← |

← |

← |

← |

← |

2 |

3 |

| AISI-420 |

2 |

4 |

1 |

1 |

← |

3 |

3 |

2 |

← |

3 |

← |

← |

← |

← |

← |

← |

← |

2 |

3 |

| AISI 420C |

2 |

4 |

1 |

1 |

← |

3 |

3 |

2 |

← |

3 |

← |

← |

← |

← |

← |

← |

← |

2 |

3 |

| AISI 440C |

2 |

3 |

2 |

2 |

← |

2 |

2 |

3 |

← |

4 |

← |

← |

← |

← |

← |

← |

← |

3 |

2 |

| AISI 304/302 |

2 |

1 |

1 |

1 |

1 |

1 |

2 |

2 |

1 |

4 |

2 |

2 |

2 |

2 |

😑 |

2 |

2 |

1 |

1 |

| AISI 316 |

2 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

2 |

4 |

← |

2 |

1 |

2 |

1 |

1 |

1 |

1 |

2 |

| AISI 1085 |

3 |

← |

4 |

4 |

← |

← |

← |

← |

← |

← |

← |

← |

← |

← |

← |

← |

← |

2 |

3 |

1=Excellent 2 = Good 3 = Fair 4 = Poor

← Will not withstand corrosion

😑 Varies

* = satisfactory only over 75% concentration

"For competitive pricing, get in touch for best prices."